QUICKO T12-K T12-C4 T12-BC2 T12-D24 IL Electronic Soldering Iron Tips Solder Iron 220v Welding Tip For Soldering Repair Station

Features:

1.Applied to soldering station FX-951/FX-952/FX-950/FM 203;

2.Lead-free, environment-friendly, 100% conformed to ROHS standard, lead and lt; 0.1% wt;

3.The technical indicators reach to original standard;

4.Use under 400 degree temperature(±20 degree), it can have 50000 solder joints.

NOTE: The new T12 tips will experience temperature jitter when first used. Don’t worry, this is normal. When you use it a few times, the temperature will gradually stabilize.

T12 tip kits contain:

Set1: 2pcs iron tip

set2: 3pcs iron tip

set3: 4pcs iron tip

set4: 6pcs iron tip

set5: 8pcs iron tip

set6: 10pcs iron tip

Please left message when you place the order,You can choose the types as you need, if you not left message for me,we will send random tips for you!Hope you can understand!

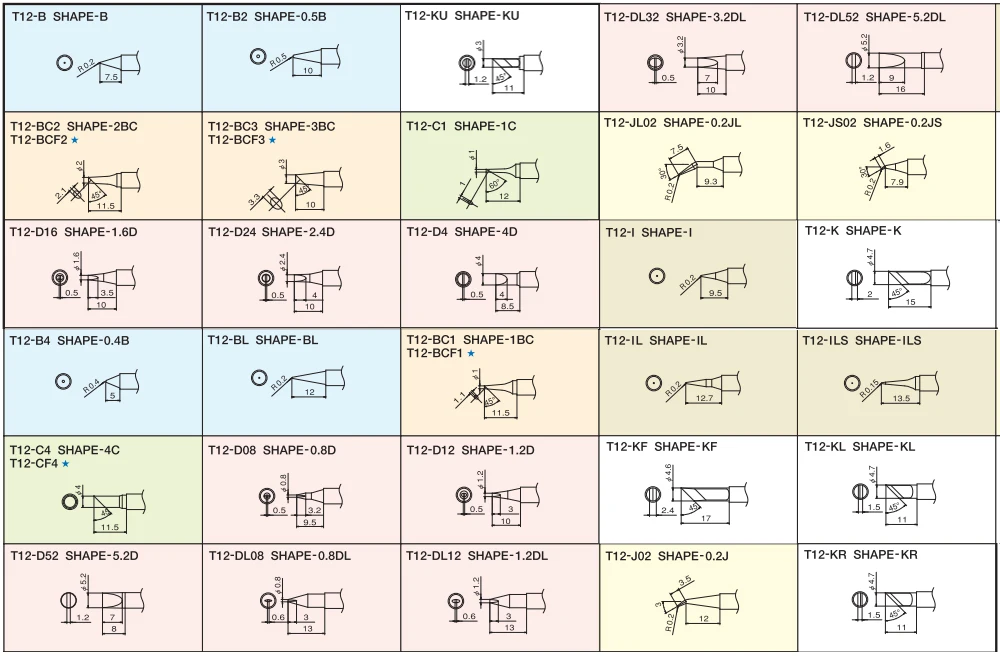

You can choose any tips from the below photo:

FAQ:

1. Why the temperature of the new T12 solder tip is jump?

Because the inside heating core of the new T12 solder tip did not go through the high temperature, so the first time to use will be a bit of temperature, generally without special treatment, the normal use of 1-2 days after the basic will not bounce. Such as the need to immediately effective, the general proposal to adjust the temperature to 380 ℃ -400 ℃, side of the solder tip to the tip of tin, burning 5-10 minutes after the shutdown, until the solder tip of the cooling and then re-boot! ( if 1 times no effect, then can be repeated 2-3 times). T12 is pulsating temperature warming, even if the display temperature is flashing, the tip of the real temperature is completely stable.

T12 jump temperature also are connected with the temperature control board of procedures, power of electrostatic and if it connect the ground.

2. What the problem of attention when we use the T12 first time?

T12 tip heating speed is very fast, when the new solder tip connect the electricity, it must be tinput immediately to the solder tip, for protection, due to heating up fast, just need 6-10 seconds, no have more time to you for preparetion.

so the important is prepare the items which will be welded, and finally boot power, and each welding gap or the end, should be more on the tin to protect and then shutdown, so it can avoid to tin the new sold tip is difficult, especially the T12 tip type of iron, such as T12-I / T12-IL / T12-BL / T12-ILS and so on!

3.What are the precautions for using the T12 tip?

a. If can use low temperature, then do not high temperature: T12 is constant temperature control, the general recommended working temperature control between 300 ℃ ~ 380 ℃, higher than 380 ℃ damage the coating of solder tip and cut down the PTC life!

b. Do not dry: the first time to use solder tip, should be wrapped while heating a layer of tin. If it’s without work, at once shutdown!

c. Diligent to clean: before shutting down, use a wet sponge or detin the ball to remove the tip of the oxidation of debris, on the tin after the shutdown power off!

d. Standard operation: Do not violent collision the solder tip, do not stamp the top of the hard objects, but can not be used to hot plastic and other materials, specifically reminded that friends like tin should avoid the iron and other hard metal knock tin, the heating core of T12 is in the head of the solder tip, often percussion is a fatal damage to T12!

e. Less use of scaling powder: scaling powder can not be used, can be used as less as possible! When scaling powder help make beautiful and reliable welding at the same time, but also greatly speed up the consumption the coating of the solder tip, T12 heating core high temperature position is very near of the Nozzle tip of the solder tip,Scaling powder in the fear of threat to T12 head pressing parts.

4.How to do when T12 tip does not absorb tin?

T12 iron head does not absorb tin, generally there are two reasons:

A. The head of solder tip is severe oxidation can not absorb tin.

B. Temperature can not rise up then can not tin.

C. The head is oxidized and can not the tin, you can use the soldering iron to clean the ball gently, then use the wet sponge rub and then heat the tin.

D. serious oxidation of tin, you can use more than 900 mesh sandpaper gently rub, with a small wooden board,

in the board to dig a small hole, put the rosin and tin in the hole, put the head of solder tip insert the hole, while heating and putting the tin,If you can prepare a tin stove, use scaling powder into tin stove put the tin to repair!

E. If T12 temperature can not rise up, the multimeter transferred to 20Ω stalls, test T12 solder tip positive and negative ring resistance. 8-10Ω belongs to the normal range, the factory standard is 8.4Ω, after using the resistance will be slightly changed!

Payment

1. 100% payment before delivery, please make sure you have make out the complete correct information, include full name, detail address, post code, phone number, the goods will be shipped to the address that you left in the order, and “P.O. box” is not allowed in the address.

2. We prefer payment through ESCROW which is a security way for you. If you want to pay by other ways, please contact us.

3. When you place an order, please choose a shipping method and pay for the order including the shipping fee (except for free shipping).

Shipping

1. We will send the items within 1-7 days once your payment is completed.

2. We only ship to confirmed order addresses. Your order address MUST MATCH your Shipping address.

3. The images shown are not the actual item and just are for your reference.

4. SERVICE TRANST TIME is provided by the carrier and excludes weekends and holidays. Transit times may vary, particularly during the holiday season.

Feedback

1. Our goal is 100% positive feedback and 100% customer satisfaction. We do our best to serve our customers the best that we can. Your satisfaction and positive feedback is very important to us.

2. If you are not satisfied with the items you ordered, please contact us before leaving negative feedback. We can work together to resolve any dispute.

3. Please leave positive feedback and 5 stars if you are satisfied with our goods and services.

Taxes

Import taxes rate are made by your customs, it is vary from different countries, so all of our products don’t include any taxes, you need to pay it on your side when necessary. …

Return and amp;Refund

1. You have 7 days to contact us and 60days to return it from the date it was received. If this products is in your possession more than 7 days, it is considered used and WE WILL NOT ISSUE YOU A REFUND OR REPLACEMENT. There are NO EXCEPTIONS! Shipping cost is bear by buyer.

2. All returned products MUST BE in the original packaging and you MUST PROVIDE us with the shipping tracking number, specific reason for the return, and your PO#.

3. We will refund, upon receipt of the item in its original condition and packaging with all components and accessories included, AFTER BOTH Buyer and Seller cancel the transaction from aliexpress. OR, you may choose to have a replacement.