Our online shop:

| Maximum circuit board area: | 400*290mm |

|

Number of mounting heads: |

4 |

| Maximum movement range of Z axis: | 20 mm |

| Maximum mounting rate: | 9,500 PCS/hour |

| Average mounting rate: | 8,000 PCS/hour |

| Positioning accuracy: | 0.01 mm |

| Buffering range of suction nozzle: | 4.5 mm |

| Power supply: | 220V/110V, 50 Hz |

| Compressed air: | 0.6-0.7 Mpa |

|

Average power: |

400 W |

|

Recognition Mode: |

Four Heads Synchronized Recognition |

|

Number of cameras: |

a Mark camera, four high-speed cameras, a high-definition camera |

| Product weight: | 210KG |

|

PCB access mode: |

automatic Left-in and right-out access, supporting left-right device connection function |

|

Quantity of trays: |

Up to 48 non-feeder feeding components are supported, each of which can specify its coordinates within the mounting range. |

|

Complex speed to mount resistance and Chip: |

6000/h |

|

Mounting accuracy range: |

0201-40*40mm,Pin spacing 0.3mm Chip(Matching which support electric feeder can mount the 0402,0201) |

| Quantity of feeders: | 50 PCS |

| Service motor: | Panasonic servo motor |

|

Guide rail: |

Taiwan TBI Linear Guide rail |

|

Driving mode: |

Taiwan TBI ball screw |

|

Nozzle Vacuum Source: |

Japan CKD High Speed On-off Vacuum Generator with Vacuum Damage |

|

Minimum air capacity of pump: |

80-120 L/min, volume more than 60 L |

|

Gas quality requirements: |

oil-water separation device, dust filter device, air pressure stabilization device |

| Dimension: |

900×1140×900mm |

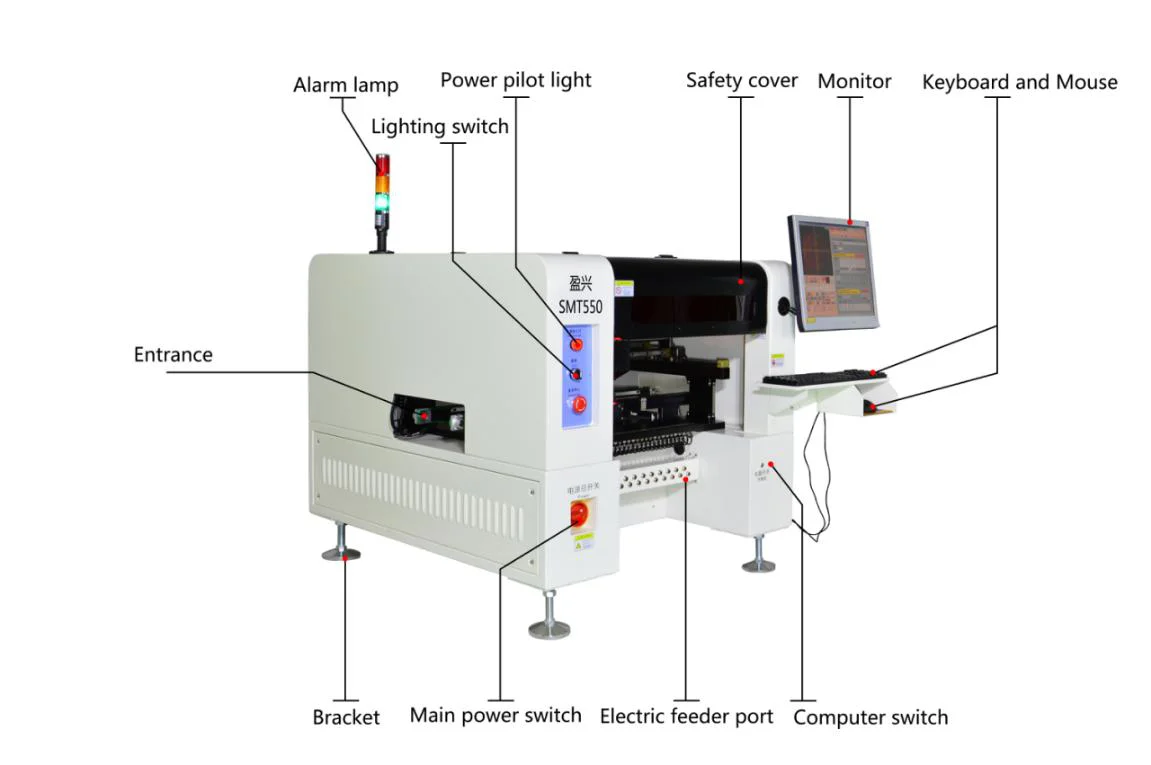

1.Description

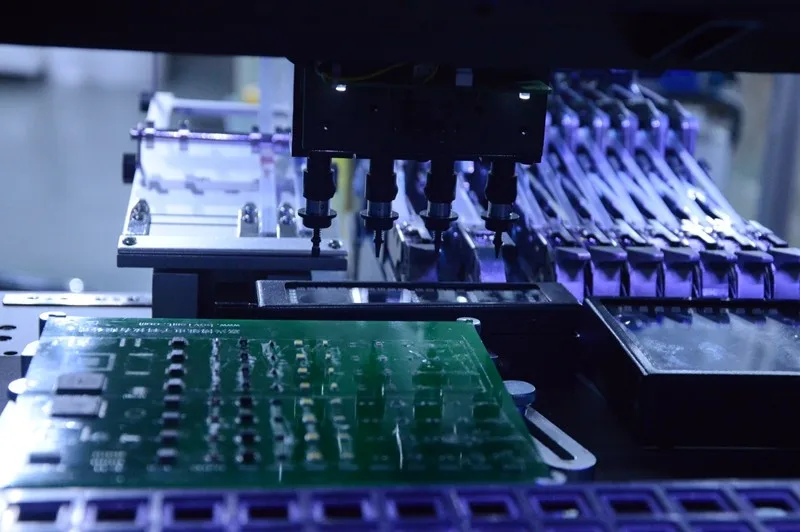

2.High Precise JUKI Universal Nozzle+4 Placement Head

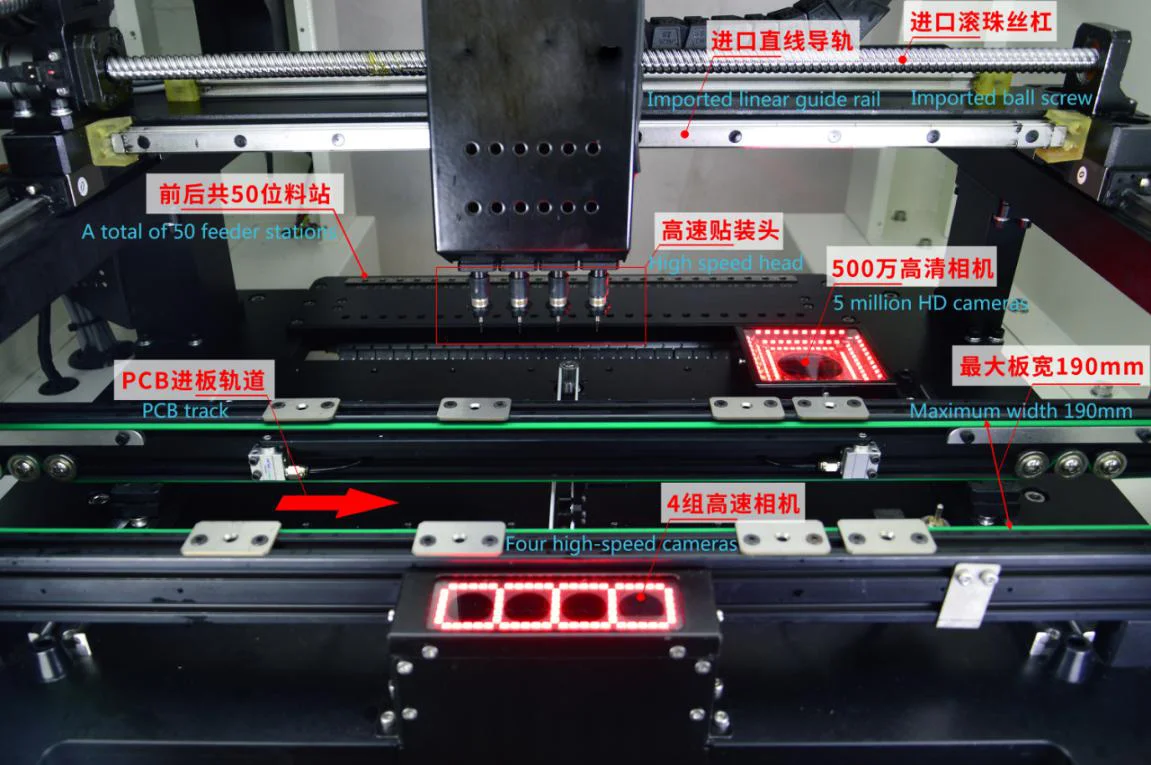

3.Internal details

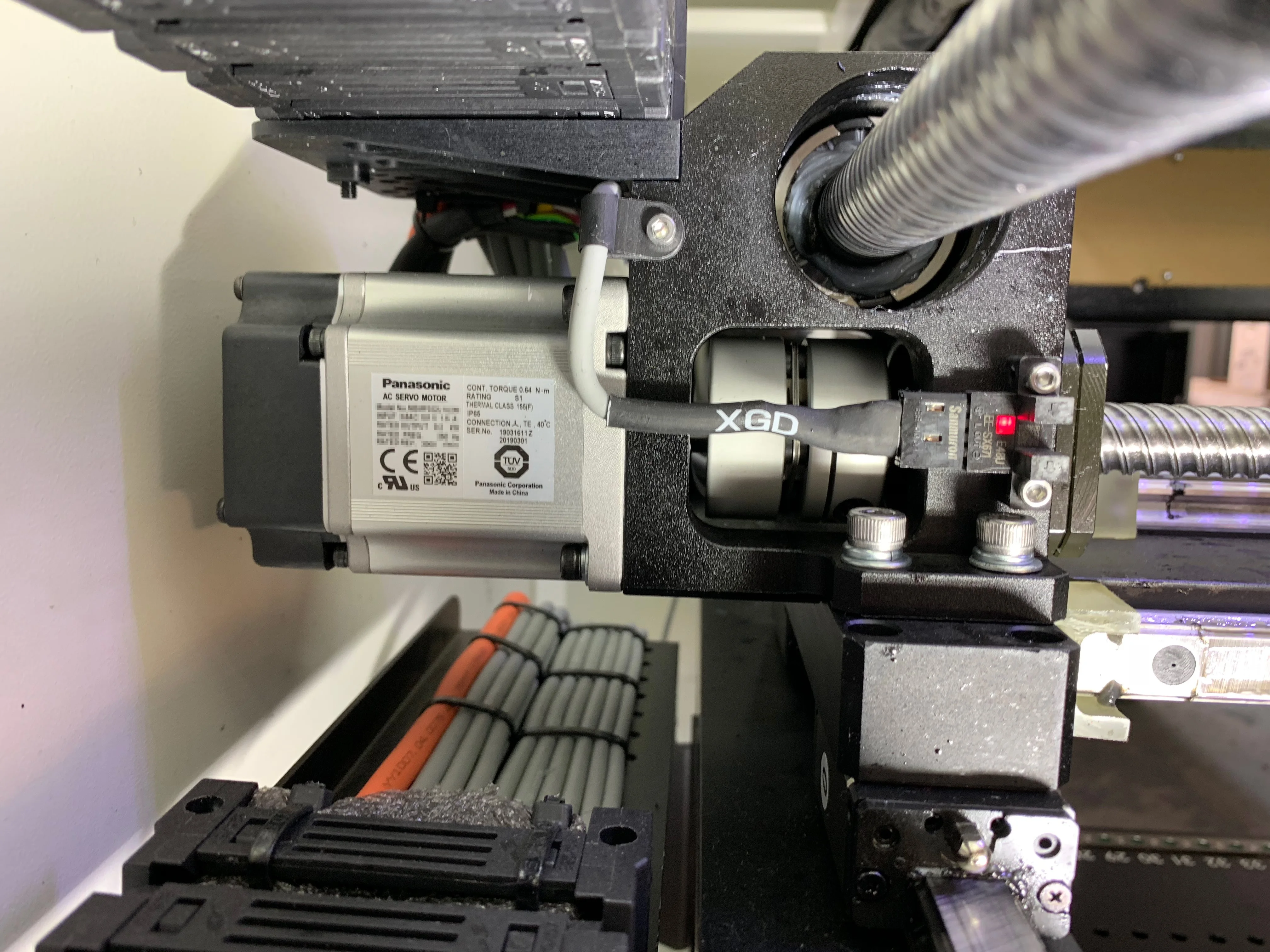

4.Panasonic Servo Motor

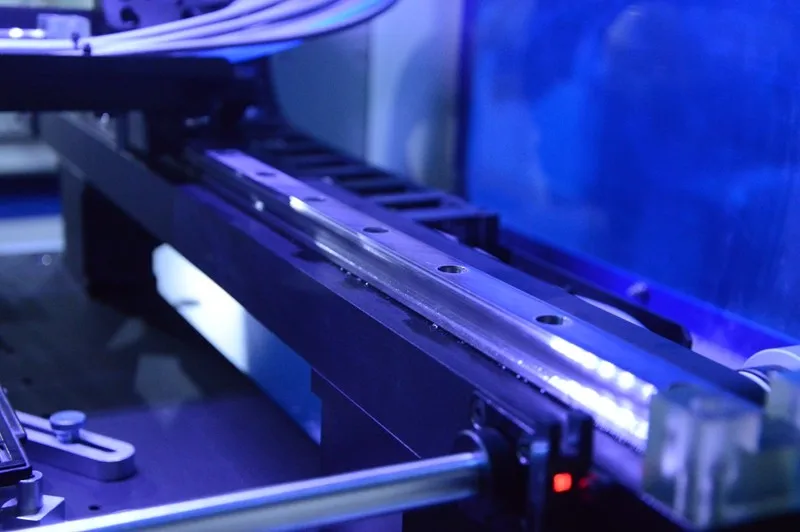

5. Screw Guide

6.Linear guide rail

7.The port of the Electric feeder for 0201

8.Package