Shiny gold finish coin die stamping

Advantage:

(1) MOQ :100 pcs

(2) Many years of production experience, mature craft.

(3) Nickel and lead free, low cadmium, comply with the Euro test requirement.

(4) Free artwork and design. All size is welcome.

(5) Pass the factory audit from TCCC ,CE,SEDEX(SMETA) audit.

(6) Reliable quality and considerate service.

(7) On time delivery.

| Size | 1.5″, 1.75″, 2″, 2.25″, 2.5″, 3″ |

| Thickness | 2mm,2.5mm,3mm,3.5mm,4mm,5mm,6mm |

| Material | Brass, Copper, Zinc alloy, Iron etc. |

| Process | Die strucking/die casting |

| Plating | shiny finished: gold/silver/nickel,copper,brass antique finished: antique gold/antiquesilver/antique copper/antique brass daul finished: daul shiny plating/daul antique plating |

| Painting | soft enamel,imitation-hard enamel,hard enamel |

| Epoxy | with/without,as customer request |

| MOQ | 100PCS |

| Sample time | 7days after artwork confirmed |

| lead time | 12-15 days after sample confirmed |

| Shipping | by air express: DHL TNT FedEx UPS by sea:from ShenZhen or HongKong |

| Payment | T/T,Paypal,Western union,L/C |

| Imitation Hard Enamel coin | Feature 1.Colors are flat and same level as the metal contour. 2.Border can be made with 9 different patterns of diamond cut. 3. Brass coin usually is heavier than zinc alloy coins while spec. is the same. 4. Motifs of brass coins are made by hydraulic stamping 5. Motifs of zinc alloy coins are formed by die casting |

|

|

| soft enamel coin | 1.Colors are lower level than the metal contour. 2. Epoxy covering is optional. 3. Border can be made with 9 different patterns of diamond cut. 4. Brass coin usually is heavier than zinc alloy coins while spec. is the same. 5.Motifs of brass coins are made by hydraulic stamping 6.Motifs of zinc alloy coins are formed by die casting. |

|

|

| Zinc Alloy Coins | 1.Zinc alloy coin is lighter weight than brass coins while spec. is the same. 2. Colors can be made with soft enamel or imitation hard enamel colors. 3.Diamond cut borders (9 different patterns) are applicable too, but the cutting border made on zinc alloy coins will be the same tone (finishing) as the main coins because we do plating after diamond cutting. 4. If you need 3D cubic designs more relief, zinc alloy is the best choice because motifs and designs are formed by casting instead of stamping. 5.Free cut die charge if coins with open areas. |

|

|

| Mirror Effect | 1.Motifs on both sides can be 2D flat or 3D relief. 2. Hydraulic stamping instead die struck stamping 3. Finished coin is shiny (mirror like) with raised parts in matte effects. 4. Finishing must be bright gold, silver, nickel, or copper plated. 5.Antique or satin finishing are not suitable for mirror effect. 6. Diamond cut edges ribbed edges are all available |

|

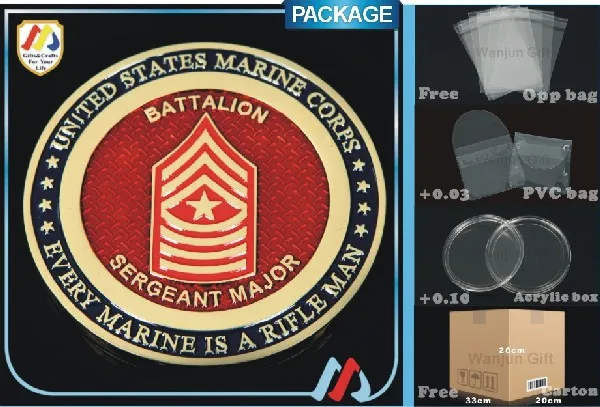

| Packaging | Details |

1pcs/opp bag, 250pcs/carton. |

| Inner box Size | none | |

| Carton MEAS | 33*28*20CM | |

| N.W. | 12.5KG | |

| G.W. | 13KG | |

| Remark | welcome personalized pack |

Our Services