SALE 5% OFF

The case surface has a layer of white protective film,protectThe membrane comes with stainless steel plate,After the chassis processing film will cause a lot of scratches, generally tear off the film will not,Do not rule out a few chassis will have a little scratch,But it does not affect the use of the product,If you mind, please don’t shoot,thank you!

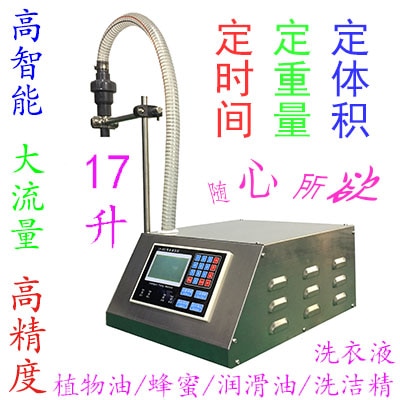

LH-852 —— Intelligent filling machine

This product is profitableUsing microComputer on pump during working hours、Speed and other factors to control,The output is accurate、Liquid filling equipment with small repetition error。The product adopts self-priming pump,It can work continuously for a long time with low noise,Suitable for filling ordinary liquid and viscous liquid。And it has oil resistance、heat-resisting、Weak acid resistance、Weak alkali resistance、Corrosion resistance, etc,It can be widely used in food、Drinks、medicine、chemical industry、Grease、Cosmetics and other industries。

Peer products need to repeatedly adjust the time to control the output,

Our productsThe automatic quantitative filling can be realized only by inputting the weight!

Especially suitable for liquid products retail!

Product advantages:

1 High filling precision:The deviation is less than1% ,With deviation correction function

2 High filling speed:17rise/minute(water),Adjustable speed1-99%

3 High intelligence:There is automation、Inching mode,With filling parameter learning function

4 Multiple quantitative units:time:S weight:g、kg volume: ml、 L

5 Single point calibration:The weight of the same product is calibrated around the weight,It needs to be recalibrated when changing the filling volume accurate,WeOnce calibrated,All weights can be filled accurately!

6 Wide operating voltage range:communication110-220Vcurrency

7 All digital keyboard:Modify parameters and input numbers directly,You don’t have to press the plus and minus keys to add or subtract slowly

8 Bilingual menu

water、Alcohol、milk、Soybean Milk、soup stock…

Filling of viscous liquid: about7rise/minute

vegetable oil、Yogurt、Detergent、Shower Gel、Washing liquid、shampoo、Honey、Color paste、Wood glue…

Is it convenient to watch video——Operation video: http://v.youku.com/v_show/id_XMTY5NTAyODkwMA==.html?from=y1.7-2

Whether filling is accurate or not——Calibration video: http://v.youku.com/v_show/id_XMTY5NDc3NTE2OA==.html?from=y1.7-2

Filling honey video: http://v.youku.com/v_show/id_XMTc4MDExNDc2MA==.html

Copy the URL to the address bar to watch the video

Product parameters:

Size of non feeding nozzle:External20within15mm (Large flow filling does not require a feeding nozzle) With discharge nozzle6Specifications:6mm(external diameter)/1.7mm(internal diameter),8/4,9/6,14/10,18/12,19/13

Panel introduction:

Delivery list:

1. host、power cord、Foot switch、Bracket、Nozzle suit、One instruction manual

2. Nozzle specification:6mm(external diameter)/1.7mm(internal diameter),8/4,9/6,14/10,18/12,19/13

matters needing attention:

1. The machine must be effectively grounded in the case(A grounded power outlet or wire the enclosure to the ground)In case of use,Otherwise, there is a risk of electric shock;

2. Warranty tube parameters:250V1A,It is forbidden to replace other parameter insurance,There is a spare fuse in the fuse seat;

3. The filling accuracy must be verified and calibrated several times before and during each use,Loss due to filling deviation The manufacturer does not assume any responsibility;

4. When filling viscous liquid, do not install any filter fittings on the feed pipe,And to ensure that there will be no debris in the liquid causing pump blockage

5. General customers please use non speed regulation channel(The speed cannot be adjusted in this mode,More stable work),If the container is small If the flow rate is too high for filling, the speed regulating channel can be selected,The speed can be adjusted only in speed control mode;

6. The filling of viscous liquid will drop after stopping now,Due to the poor fluidity of viscous liquid,Liquid sticking to the nozzle of automatic valve

The body can’t be dripped out immediately,Liquid with good fluidity, such as water, doesn’t do this,Filling machine with large diameter nozzle

thiskind,The small nozzle can be replaced;

7. Clean water must be pumped circularly at the end of each filling,Clean the inside of pump head,Otherwise, the residual liquid may be chemical with the pump head The pump head is damaged due to reaction,Causing little or no suction;

8. Avoid contact with corrosive materials,Keep away from high temperature and humidity.

Calibration techniques:

1. If it is used for batch continuous filling,Filling is required before calibration10kgCalibrate the machine after the liquid is preheated,Because it’s continuous When the temperature of the filling controller rises, the output will increase;If the interval is long,Do not preheat the machine directly set.

2. Output during calibration1.5About kilogram of liquid,This weight calibration is most accurate。

common problem: 1 ask:Why can’t the speed be adjusted?

answer:It is not possible to adjust the speed in no speed mode,Press and hold“set up/menu”Enter the menu without releasing the key—output—Select speed regulation that will do, The working life of the machine is longer when the speed is not adjusted,It is recommended to select the non speed regulation mode when it is not necessary

2 ask:Why does the filling end drip?

answer:This happens to all large nozzles,Please replace the small nozzle。Due to the poor fluidity of viscous liquid,Liquid sticking to the nozzle of automatic valve The body can’t be dripped out immediately,Liquid with good fluidity, such as water, doesn’t do this

3 ask:How to drain all the liquid in the pipe?

answer:Remove the feed pipe from the liquid container,The discharge nozzle takes out the material from the bracket and sags naturally,Filling machine upside down(Display down), QiThe liquid can be emptied by moving the filling machine

4 ask:How to clean the residual liquid inside the filling machine?

answer:Cleaning method of filling machine:Set the filling volume to0,Start the filling machine and pump cleaning agent or water circularly。

5 ask:What are the specifications of discharge nozzle?

answer:Nozzle specification:6mm(external diameter)/1.7mm(internal diameter),8/4,9/6,14/10,18/12,19/13

6 ask:Can you fill honey?

answer:Baume degree less than41All honey can be filled directly,If it exceeds Baume degree41Or crystal honey needs to be heated before filling

7 ask:Is filling honey fast?

answer:Honey Baume Degrees39degree1000The gram is probably12second,You can refer to it

8 ask:What is the reason why the pump makes a noise when it starts but can’t be pulled out?

answer:a. The pump is completely dry,Disposal method:Fill the feed pipe with liquid and lift up the rear end of the filling machine to allow the liquid to flow into the pump, Then start the filling until the liquid is pumped out b. If methodainvalid,Foreign matter may be stuck in the pump head,The front end of the pump needs to be disassembled4Big screw and pull out the screw,Clear any Foreign matter and rinse clean,Install as is,Retest。The four screws must be tightened,If the air leakage is also unable to correct Regular working c. Pump head damaged,The pump needs to be replaced

9 ask:What kind of liquid is suitable for filling?

answer:Suitable for liquids:Alcohol、water、Honey、vegetable oil、Lubricating oil、Washing liquid、Shower Gel、Shampoo, etc

10 ask:What are the packing specifications?

answer:Gross weight:8.5kg Box size:long410xwide370xhigh215mm