No Need to Purchase, Please See our NIJ IIIA Ballistic Panel’s Warranty Below

*** Click Here and add our store to your Favorites ***

Buy With Confidence! Our Pledge to you:

- We will use our 14 years of experience as a Manufacturer to Ensure that you have a pleasant buying experience.

- We will answer all questions and inquiries as soon as possible.

- We will ship your orders in a quick and efficient manner.

- We will leave positive feedback and hope we will gain yours too

Shipping:

**We use Aliexpress’s shipping calculator to determine shipping costs. We do not charge a handling fee.

**We use mainly commercial delivery service such as Fedex/DHL/TNT/UPS/EMS/SF-Express/Toll for our high valued items. Please refer to our listing and feel free to contacts us if you have any question.

**We ship Monday through Friday (excluding holidays) and most Saturdays. Orders paid for and payments cleared by 4pm China time will be shipped the same day.

This is Only a warranty page, price indicated for the product does not exist. It is for the purpose of showing our product’s guide and reference.

Q: What is Aramid in general?

A: Aramid fibers are a class of heat-resistant and strong synthetic fibers. Aramid is a short term for aromatic amide and refers to a reinforced fiber with tensile strength five times as strong as iron given the same weight, light weight, excellent heat resistance, and low cut resistance. This product is very widely used in industries that require high strength and lightweight materials. Dupont’s material (Begin with “K”), Honeywell’s Spectra, Teijin’s Twaron, Kolon’s Heracron are all part of the Aramid family.

Q: Why all your panels are Thermo Sealed on the edges?

A: This is to protect the Aramid Material away from moisture. Aramid’s performance is very stable and long lasting–This is based on the condition that the material has not been exposed under Sunlight (UV) or being contacted by moisture. The covering cloth may do good in UV resistance and stop water splash, but sewing finishing will not stop the moisture get into the cover because there is always moisture in air and it will get inside the panel, Aramid will absorb the water then ended “Non-Ballistic”.

ITS PROVEN THAT THERMO SEALED PANELS PROVIDE BETTER PROTECTION AND LAST LONGER !

This means you can use damp cloth to clean our panels whenever you wanted where needed, our panels will remain functional even if you dropped them in water–It’s Great for Quick Release Carriers.

Q: How does your ballistic material look like?

A: Our ballistic material used for Aramid panels is laminated, similar to Goldflex and is very light.

Q: Is your body armor NIJ Certified?

A: We don’t produce the Aramid UD material, we source directly from reliable manufacturers and Yes our suppliers are NIJ Certified Suppliers.

Q: What about your V50 ballistic limit performance? Have you tested your products on such standards?

A: All our NIJ IIIA rated Ballistic Helmets and Aramid panels listed have been tested by world famous ballistic labs on their V50 performance. In case you are interested in seeing the ballistic test report, please feel free to contact us.

Q: What is the highest level your soft armor panels (SAPS) could achieve?

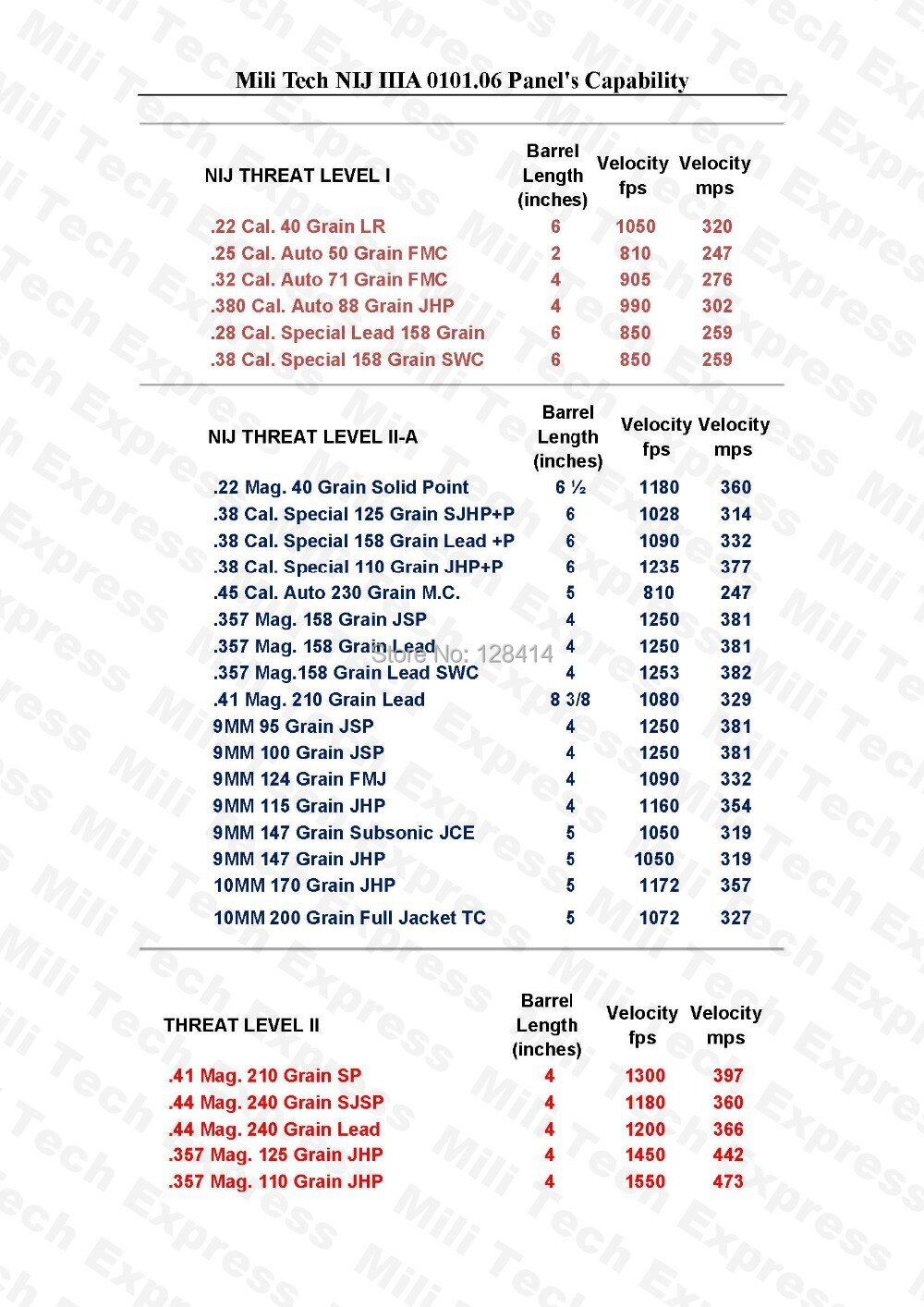

A: Our SAPS are made to the NIJ IIIA 0101.06, this means it will stop all bullets listed in the NIJ IIA, NIJ II and NIJ IIIA system. NIJ IIIA 0101.06 is the latest standard for body armor, standards such as 0101.05/0101.04 were old standards and their measurements on velocity were lower than the latest version. For higher threats such as NIJ III or NIJ IV level, you will require hard armor to achieve such ballistic purpose because NO SOFT ARMOR CAN REACH SUCH LEVEL.

Q: Why is your soft body armor heavier than some other sellers’ products?

A: If we are making comparison between Aramid panels, our panel shall be marked on the lighter scale side, however if you are comparing with UHMWPE panels (Dyneema by DSM, Spectra by Honeywell and so on) then Aramid is not in the place of winning at all in terms of weight because they are totally two different materials, yet at different stable levels too when placed in different conditions such as temperature.

We have seen some sellers listing USA MADE EXTREMELY LIGHT ARAMID CORE soft panels at very low prices, we were so curious about their weight and amp; cost control, until we looked into their ballistic test report — Not surprised as they dealing TOTALLY DIFFERENT QUALITY PRODUCTS–Their ballistic test report shown the Trauma were way over 44mm–According to NIJ IIIA 0101.06 requirements, any ballistic panel’s trauma that is bigger than 44mm, is considered a dis-qualified product. Not to mention the trauma impact could kill the person (Just imagine a bruise caused by a sharp object at over 44mm depth on your body), the chance of bullet penetration is also very high, for those who believed they got a bargain deal, all that we can say is good luck with their panels.

Our body armor panels were specially designed and made to over-achieve the NIJ IIIA 0101.06 standard (Back Face Signature for example), it has been tested under extreme environments by HP White with proven stable performance. We also include trauma pad in our panels to reduce BFS damage which would thicken the panel by adding a few grams in weight too.

Q: There are other Sellers claim their soft armor panels (SAPS) are also stab resistant, does your panel work the same?

A: Unfortunately our soft armor panels (SAPS) are made for ballistic purpose only (unless otherwise specified), please be careful with those panels that claim to be “Double-proof” (Stab and amp; Ballistic resistant) as in many cases they will fail the NIJ level I stab test and even sometimes–the IIIA ballistic test. For your own safety we have listed key points below;

1, Stab resistant materials are usually different than ballistic materials. It usually made of hard metal or glued woven or felts or sometimes, metal wires and woven together.

2, Normal knives/needles will not go thru Lvl IIIA SAPs easily due to the panel’s thickness and energy impacted. We have seen many personal test videos on Youtube, however the test results are not stable and there was no way the energy impacted on the panel could reach 24 jouls (Energy measure used for stabbing test), not to mention NIJ Lvl I stabbing and amp; Spike standard has the 36 jouls limit requirement, it would be a real disaster when such panels meet special designed/made combat knifes/bayonets and someone could get hurt badly.

If you are considering a ballistic vest that is also stab proof–It is suggested to purchase a vest that is NIJ 0115.00 (Stabbing test standard) and amp; NIJ IIIA 0101.06 (Ballistic test standard) Certified and be sure the warranty covers both the ballistic and amp; stab proof performance.

Q: How come your panels look thicker than others?

A: Unlike some sellers aim for thinness, which in most cases they put ultra thin trauma pad in the SAPS (Some of them do not even have trauma pad included and sell trauma pads separately), we put trauma pad in all our panels (without trauma pads our panel is at 5.5mm-5.8mm thick) and the purpose of doing this is to reduce the chance of serious injury/damage caused by Back Face Signature. This means for the price you pay on our SAPs, you will get Ballistic Panels + Trauma Pads.

Q: What are the Warranties on your panels?

A: We offer FIVE YEARS Warranty on our ballistic panels and 12 months workmanship on the cover.

Q: Can the panel still being used after it’s been shot or the cover is broken?

A: Although the panel is highly likely to stop more shots (On it’s described ballistic capability and standard), it is not safe to use the panel again because the fiber’s structure will be damaged after impact (When bullet impacted, there will be a few layers penetrated by the ammo), and moisture in the air will start get into the layers, the panel then will losing it’s capability gradually and ended with None-Ballistic. Please replace it with a new one when you have a chance.

In addition, it is important to have your panels well maintained,to maximise its shelf life, we highly recommend you to carry the below procedures;

Avoid direct exposure under sun light and all inserts must be stored in a cool, dry place that has good ventilation where away from corrosive materials.

When in need of cleaning the inserts or ballistic helmets- Use only water damped cloth to wipe off the dirt mark. If the nylon cover is broken and you can see the aramid layers inside, you may need to contact your supplier asap and consider a replacement.

Q: Are the rest of your listed items also tested and certified?

A: All our personal body armor products listed have been tested and certified by qualified Ballistic labs, which majority of the reports were done by H.P White. WE GUARANTEE ALL OUR BALLISTIC TEST REPORTS ARE GENUINE AND 100% TRACK-ABLE!